- 1

- 2

- 3

|

|

Products

Home>

Products

|

Super versatile labeling machine

It is suitable for high-precision labeling of flat bottles on one and two sides. With the addition of a round bottle labeling mechanism, it can be used for positioning and labeling of round bottles, and even four- or three-sided enveloping labeling of square bottles, special-shaped bottles and square bottles, greatly improving The scope of use of the equipment completely solves the big problem of multiple use of one machine for economic users and users who pursue efficiency.

- Features

- Technical Parameter

- Application Video

- Product Introduction

◆ Header

1. Multi-dimensional space adjustment: The header can realize 8-dimensional space adjustment, tilt angle adjustment, additional position display, and accurate positioning adjustment.

2. Horizontal translation of the header: The fine adjustment of the labeling position can be achieved by horizontal translation of the header during the work of the header.

3. All adjustment mechanisms can be adjusted quickly without tools.

4. The double pressure roller design is adopted to fully improve the tension of the label, which is especially beneficial to the labeling of ultra-thin labels.

5. All structural parts are processed by numerical control, and the parts are matched with high precision to ensure the accuracy of the equipment.

6. The new label clutch makes the tension more stable and runs more smoothly. The three-point head up and down adjustment device makes the adjustment smoother and the target plate more stable.

7. Special scraper bracket for easy adjustment.

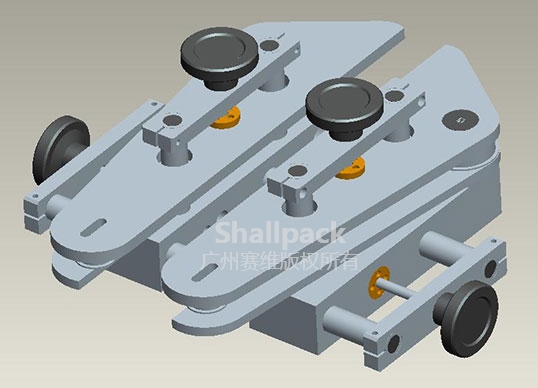

◆Pressing mechanism

1. The main motor is driven by a double-row chain to increase the transmission torque and reduce the deformation of the chain.

2. Separate pressure belt pads are conducive to heat dissipation, and different pressure settings can be used according to the requirements of different workstations.

3. The pressure belt is supported by a large span, with double screw adjustment, and the screw is driven by a chain to realize synchronous adjustment.

4. Increase the belt buffer slider to reduce the wear of the press belt and improve its mechanical performance.

5. Wide range of height adjustment, the adjustable area is 0~400mm, which is convenient for changing product types.

◆Orthopedics

1. Using mechanical transmission, the main conveying line, pressing belt and shaping belt are driven by gears, driven by a high-power motor, fully synchronized operation, and stepless speed regulation can be realized.

2. It adopts enlarged spiral bevel gear transmission to improve the safety performance of operation.

3. Two-dimensional space adjustment to increase the scope of equipment application.

4. The chain of polymer material is used, which is conducive to the accuracy of plastic surgery.

◆Conveying line

1. High-precision conveyor belts are used to achieve absolute synchronization between the conveyor line and the press belt.

2. The widened strip design and high-power motor drive expand the application range of the equipment. Improve the running inertia of the conveyor line and obtain higher labeling accuracy.

◆Positioning mechanism

patented design (patent number: 200620058757.7) is a secondary positioning mechanism applied to a linear labeling machine. It is also the highlight of the double-sided labeling machine, which completely solves the labeling problem of special-shaped bottles. When pasting special-shaped bottles, you can first make different positioning blocks according to the cross-sectional characteristics of the pasted bottles, and install the positioning blocks on the eccentric block of the positioning mechanism. When the pasted bottles pass by, the positioning molds are quickly closed, and then they The same linear speed will be sent out of the bottle, and the position of the affixed object after positioning is accurately positioned between the pressing belt and the conveying line.

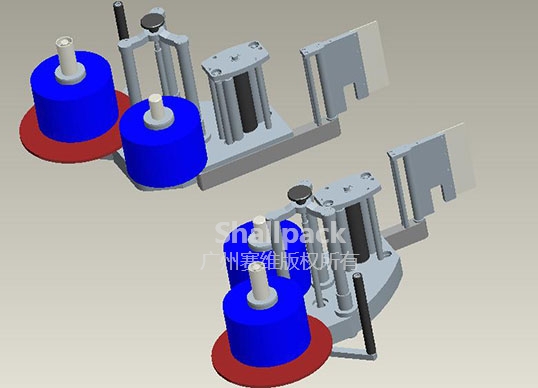

◆Large round bottle labeling mechanism

1. The newly developed round bottle labeling mechanism can realize the positioning of the bottom of the bottle, and the maximum labeling speed can be increased to 120 pieces/min.

2. It can be adjusted and replaced quickly, which facilitates the switching between flat and round bottles, shortens the switching time and improves production efficiency.